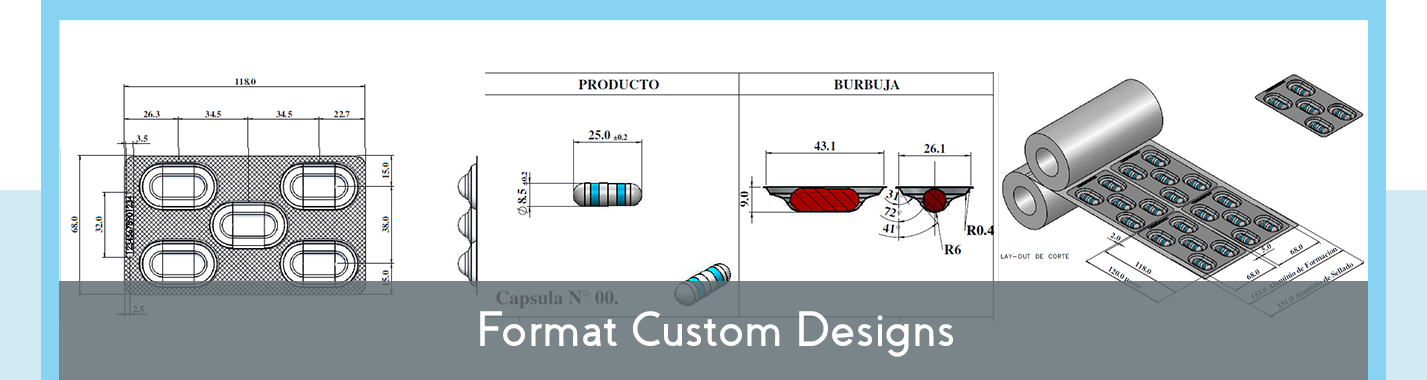

Pharmapack has in-house production capabilities to make formats and tooling for Thermoforming Blister Pack (Alu/PVC, Alu/PVC-PVDC, Alu/PVC-Aclar), Cold Forming Blister Pack (Alu-Alu), and Child Resistant Foil Blister Pack.

We tailor packaging designs to your product needs, heightening your brand image and optimizing your process efficiency while ensuring that we meet every quality spec required by the conditioned pharmaceutical form.

These days, product packaging has become an effective means of communication. Consequently, primary packaging becomes important not only from an aesthetic or design perspective, but also as a differentiating value of the brand. The importance of packaging is linked to today’s consumers’ lifestyles, in constant movement, preferring smaller products that can be carried in one hand, as part of the “On the Go” trend.

We tailor packaging designs to your product needs, heightening your brand image and optimizing your process efficiency while ensuring that we meet every quality spec required by the conditioned pharmaceutical form.

These days, product packaging has become an effective means of communication. Consequently, primary packaging becomes important not only from an aesthetic or design perspective, but also as a differentiating value of the brand. The importance of packaging is linked to today’s consumers’ lifestyles, in constant movement, preferring smaller products that can be carried in one hand, as part of the “On the Go” trend.

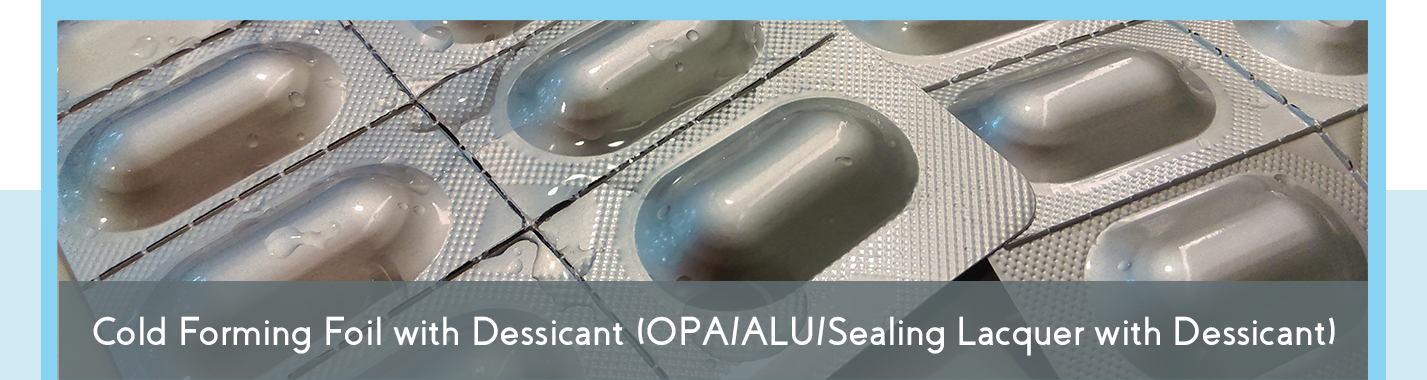

Pharmapack offers a highly reliable alternative for absolute protection from moisture, oxygen, and light by means of a cold forming tri-laminate PVC-free structure with Alu-Polyethylene sealable to Alu-Polyethylene backing structures.

The Cold Forming Foil with Dessicant offers the greatest protection available against moisture cross diffusion between the environment, the alveolus/bubble, and the pharmaceutical form (capsule, tablet) of the medicine. Its high moisture-absorption capacity significantly prolongs the product’s shelf life.

The Cold Forming Foil with Dessicant offers the greatest protection available against moisture cross diffusion between the environment, the alveolus/bubble, and the pharmaceutical form (capsule, tablet) of the medicine. Its high moisture-absorption capacity significantly prolongs the product’s shelf life.

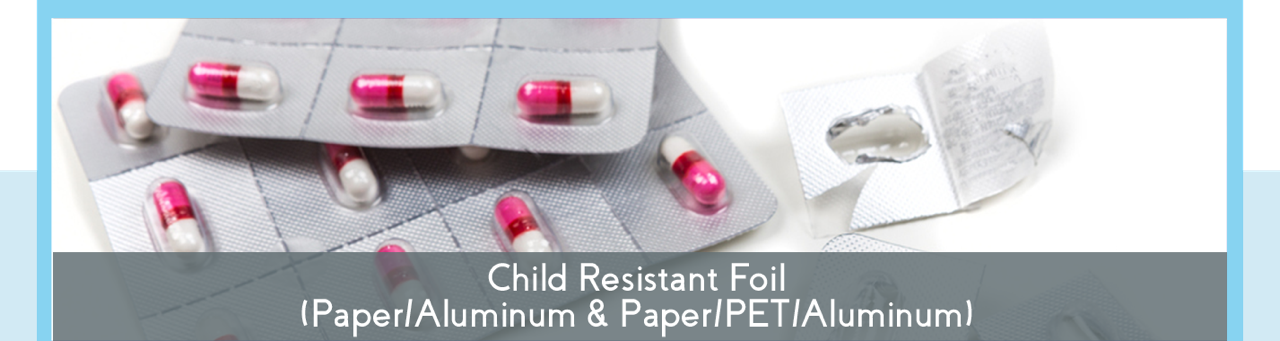

Pharmapack offers an innovative material for the blister-pack backing, whose laminate structures (Paper/Aluminum and/or Paper/PET/Aluminum) not only provide the medicine with complete protection from moisture, oxygen, and light in the blister pack, but also allow for reducing the risk of poisoning by accidental ingestion for children under 4 years of age. Such reduction is achieved via one of many opening mechanisms available (Peel/Push, Peel, Fold/Tear, and Push).

The Child Resistant Foil meets FDA regulatory standards and offers a high level of safety in the 2- of 3-step opening process to access the product:

1. An alveolus / bubble must be detached from the blister completely

2. The PET laminate is taken off, revealing the blister structure

3. Finally, the product can be pushed through the remaining aluminum layer to be consumed.

The Child Resistant Foil meets FDA regulatory standards and offers a high level of safety in the 2- of 3-step opening process to access the product:

1. An alveolus / bubble must be detached from the blister completely

2. The PET laminate is taken off, revealing the blister structure

3. Finally, the product can be pushed through the remaining aluminum layer to be consumed.

Pharmapack offers a broad range of high-specialty foil solutions geared toward safeguarding both brand and product integrity by considerably reducing the risk of drug forgery. This is achieved by means of our excellent technology, know-how, and production processes.

The primary protected packaging offers better security against drug forgery. The drug can be falsified only by having access to the materials and advanced technology.

The primary protected packaging offers better security against drug forgery. The drug can be falsified only by having access to the materials and advanced technology.